Materials We Use

There are 2 ways to make hardwood flooring, engineered and solid. In all our products, they are available in engineered construction or solid. Which type of construction should you choose?

Engineered hardwood flooring

Generally, engineered flooring costs a bit more than solid hardwood flooring but it has its benefits and it’s worth every cent if you choose to go this route. Engineered hardwood flooring has a solid wood top that is glued to a plywood base. We use only the best plywood in the world to make our engineered flooring; Baltic birch. Each layer of ply is only 1.5 mm thick. High quality glue fastens each layer together with precision without voids. It is very stable and highly respected in the industry. When do you want/need to use engineered hardwood flooring?

In floor heating

With in floor heating, heat comes from the floor to heat a space. This is usually done with hydro wiring or hydronic pipes although there are other methods used. In any case with in floor heating, engineered hardwood flooring must is used instead of solid construction. The heat from the floor puts stress on the hardwood. Engineered hardwood flooring can manage this stress and stay stable throughout the seasons.The substrate or subfloor is concrete

In this situation, engineered hardwood flooring can be glued directly onto the concrete. No wooden subfloor is needed.Very little to no board movement

Engineered flooring is very stable. In this part of the world, we have 4 seasons. Sometimes as cold as -40c to 37c. With these variations in temperature come swings in relative humidity. Wood is hydroscopic. This means that wood takes on and gives off moisture according to the relative humidity around it, much like a sponge. In the winter, despite a drop of relative humidity, engineered hardwood remains stable. In the summer, when humidity can be very high, engineered hardwood remains stable.

What are the caveats to engineered hardwood flooring? Cost is usually more than solid hardwood flooring so this is a consideration. Also, the length of the boards in engineered flooring are limited to 10’. Our solid flooring can be as long as 14’. So this is a limitation but is seldom a deterrent as the lengths are still very long.

Solid hardwood flooring

Generally, solid hardwood flooring is lower in cost than engineered hardwood flooring. The manufacturing process is simpler and quicker. Solid hardwood can be installed in many situations and suitable in all sorts of applications. Our solid hardwood flooring can at times have very long boards, up to 14’.

Another very important consideration is what type of specie of hardwood to go with. Determining the right material is often critical when acquiring a certain look and feel. Some species are very warm in tone, while others are cooler. Some species take well to whitewashing or grey stains while others don’t take well at all. Some wood grains are simple while others are erratic and complex. Some woods do better than others when it comes to texture, dent resistance, stability, and board length and width. Explore some of the options. We are here to help guide you through the process.

Which plank flooring fits your vision?

Consult with our expert team and explore the perfect flooring options that will bring your creative vision to life.

Types of Hardwood Flooring

White Oak

White oak is an amazing material and yields beautiful results. It has been appreciated for its beauty, strength, and timelessness.

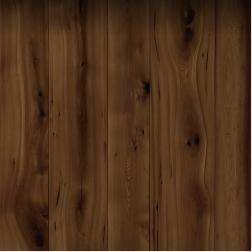

Grey Elm

Grey elm is a unique material and yields beautiful results in flooring! In Canada grey elm has been used in furniture for centuries.

Reclaimed Hemlock-Flooring

Antique reclaimed hemlock barn board flooring provides a unique, beautiful finish, once popular in Ontario barns for floors and walls.

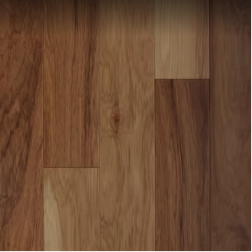

Walnut

Walnut is a distinctive choice for flooring, with a bold grain pattern and unique traits that make it truly stand out.

Ash

Ash is an excellent wood choice, producing beautiful flooring results with minimal drawbacks in flooring applications.

Red Pine

Red pine, a softwood with classic appeal, is cherished for its timeless beauty. In Canada, it's been used in furniture and flooring for centuries.

Cherry

Cherry flooring adds a unique touch to any space, darkening and enriching over time as UV rays affect the wood.

Reclaimed Rock Elm

Reclaimed Rock Elm is a unique choice for flooring, yielding beautiful results and used in Canadian furniture for centuries.

Hickory

Hickory is valued for its beauty and strength, making it ideal for furniture, carriage wheels, tool handles, ladders, sporting goods, and flooring.

Red Maple

Red maple is a fantastic wood and it’s underrated. With certain finishing techniques, it is set apart from all other woods.